The semiconductor industry is at the heart of modern technology, powering everything from smartphones and computers to medical devices and aerospace applications. The ultra important industry relies on high quality materials, especially metal alloys.

Why Metal Alloys Are Essential for Semiconductor Manufacturing

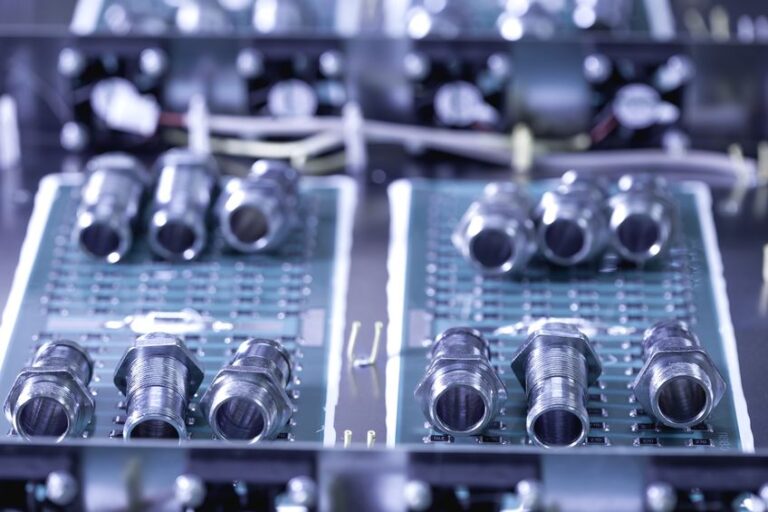

Semiconductors require materials that strike a balance between electrical conductivity and insulation. This is where metal alloys come into play. Alloys like tungsten, Molybdenum, Tantalum, and titanium are commonly used in semiconductor fabrication due to their superior thermal stability, ta'au, and mechanical strength. These metals help improve the efficiency and longevity of semiconductor components.

Meeting the Industry’s Demands with Custom Alloys

Every semiconductor application has unique requirements, e aita te mau tao'a paari e faaî tamau i te mau titauraa e titauhia. No reira, te horoa nei matou i te mau ravea no te faaafaro i te mau hinaaro o te feia hoo. Mai te reira te huru, te horo'a nei matou i te mau huru metala huru rau i roto i te mau piha haapiiraa e rave rahi, te mau hoho'a, e te rahi, Te haapapu ra ta tatou mau piahi i te mau mea ta ratou e hinaaro no ta ratou mau ravea hamaniraa tauihaa.

Na roto i te tahi atu rave'a 35 te mau matahiti o te iteraa, E ite to matou no te horo'a i te mau a'oraa teitei i te mau taime poto e te mau haereraa i mua. E hinaaro anei outou i te mau tao'a mata, te mau mea faufaa roa a'e, e aore râ, te mau tao'a taa ê no te feia, te vai ra matou i ô nei no te tauturu ia outou ia ite i te faatitiaifaroraa maitai roa a'e.

Te amui nei te hoê hoa no te hoê putuputuraa a te mau fare hamaniraa tauihaa

Eita roa ' tu te ohipa tapihooraa tauihaa e tapea i te hamani - ino - raa, E. Te oaoa nei te Eagle Alocys Corporation i te horo'a i te mau rave'a teitei i te mau rave'a aravihi apî o te faatere i te mau haereraa i mua o te mau rave'a aravihi na te ao atoa nei.

Mai te mea e, e hinaaro outou i te mau tao'a faufaa roa a'e no te mau rave'a haaparareraa, te vai ra matou i ô nei no te tauturu ia outou i te mau taahiraa atoa o te e'a. A farerei mai ia matou i teie mahana no te hoê parau faahiti tamoni ore e a vaiiho ia matou ia tauturu ia outou ia imi i te mau materia ti'a no ta outou opuaraa.