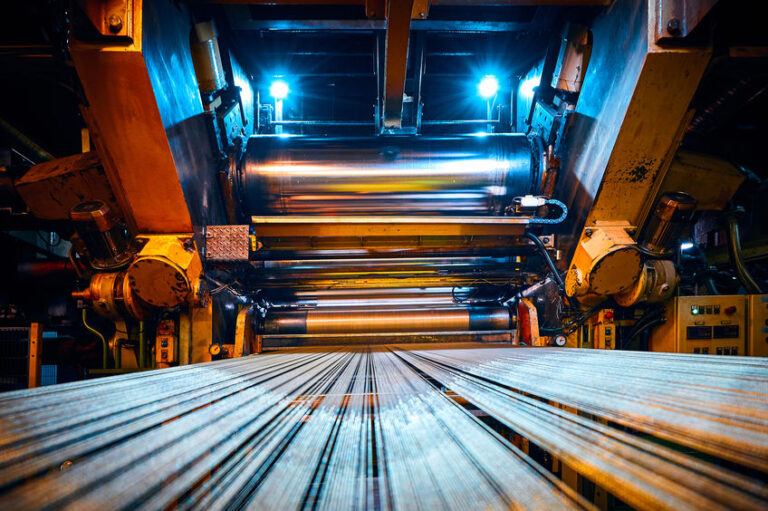

Whether you’re cutting, shaping, drilling, or milling, the right alloy can make the difference between a big difference in machine shop operations.

Not all metals are created equal, and in a high-performance shop environment, the physical properties of each alloy matter. High-strength alloys like titanium, 鎳, and tungsten aren’t just durable, they can also take a beating without compromising integrity. That’s a big deal for parts that need to perform under extreme temperatures, corrosive environments, or heavy loads.

此外, some metals offer excellent corrosion resistance but are notoriously tough on tooling. Others, like certain aluminum alloys, provide the perfect balance of ease and efficiency. Choosing an alloy that’s optimized for your process means faster cycle times, less tool wear, and better part consistency.

自訂,減低成本

用專業合金其中一個最大嘅好處就係能力 以量身訂造材料物業,以滿足正確項目要求. 自訂尺寸, 脾氣, 同埋形狀可以減少過量嘅材料廢物,同埋經常消除額外嘅加工步驟. 咁即係話生產效率更高, 你嘅機械師頭痛會少啲, 同埋更多控制你最後嘅部分質素.

供應保持你跑

我哋都知道,當材料出貨延遲嘅時候會點: 生產停止, 時間線滑動, 同埋成本上升. 所以有可靠嘅工業金屬供應商係至關重要. 我哋好多物品都可以即刻運送, 同埋根據你嘅正確繪圖,提供定制成績同成品零件嘅能力, 我哋幫助你嘅店舖繼續運作,而唔會妥協.

如果你對我哋供應嘅工業金屬有任何疑問, 聯繫我哋.